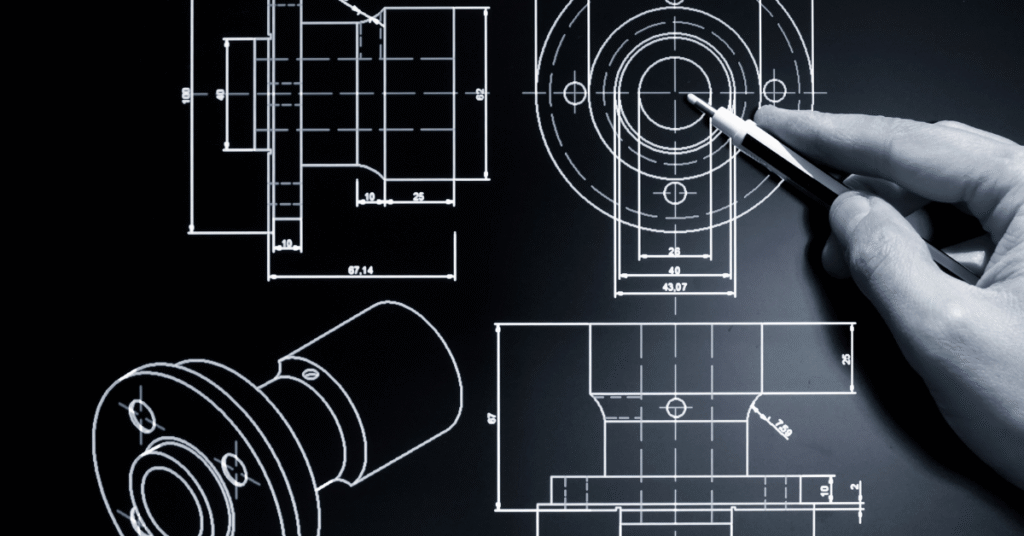

Body fabrication has undergone a significant transformation over the past decade. Traditional methods, once heavily reliant on manual labor, have now been revolutionized by Computer-Aided Design (CAD) and automation technologies. These advancements not only improve accuracy and efficiency but also reduce production time and costs.

What is CAD in Body Fabrication?

Computer-Aided Design (CAD) refers to the use of computer systems to assist in the creation, modification, analysis, or optimization of a design. In body fabrication, CAD is used to:

- Create precise blueprints for vehicle bodies, panels, and custom structures.

- Simulate the fit and finish of fabricated parts.

- Reduce human error in design processes.

- Streamline design revisions and prototyping.

Importance of Automation in Fabrication Units

Automation involves using control systems such as computers or robots for handling different processes and machinery in manufacturing. In body fabrication, automation plays a critical role in:

- Enhancing precision with robotic welding, cutting, and assembling.

- Increasing production speed while maintaining consistent quality.

- Improving worker safety by handling heavy and risky tasks.

- Reducing labor costs and human error.

Benefits of Integrating CAD and Automation

When CAD and automation work together, they bring about a revolutionary change in fabrication:

1. Design-to-Production Consistency

With CAD designs directly linked to automated machinery, there’s a seamless transition from the digital model to the physical product. This reduces miscommunication between designers and technicians.

2. Rapid Prototyping

CAD software allows quick changes in design, and automation enables fast fabrication of prototypes. This helps manufacturers test and finalize products faster.

3. Cost Efficiency

By minimizing waste, rework, and delays, manufacturers save on materials, time, and resources—leading to higher profit margins.

4. Scalability

Once automated systems are in place, it’s easier to scale up production without compromising quality or consistency.

Real-Life Application: Commercial Vehicle Body Manufacturing

Commercial vehicle manufacturers heavily rely on CAD for accurate chassis fittings and bodywork. Automation in welding and painting ensures durable and aesthetically pleasing finishes. Advanced fabrication units also use automated barcode scanning to track raw material inventory and optimize production workflows.

Future Trends in Fabrication Technology

The future of body fabrication is promising with innovations such as:

- CAD tools for smarter design suggestions.

- IoT integration for real-time machine monitoring.

- 3D Printing for creating complex body parts and components.

- Digital twins to simulate the entire fabrication process before physical production.

Conclusion

CAD and automation are no longer optional in body fabrication—they are essential tools for modern manufacturers aiming to stay competitive. By leveraging these technologies, companies can ensure accuracy, scalability, and quality while keeping costs under control.