At Himatsingka Automobiles, a leading tip trailer manufacturer in India, building a commercial vehicle goes beyond just assembling parts—it’s about transforming raw materials into powerful, road-ready machines that support industries across the nation. It all begins with a concept, where ideas take shape on the drawing board. Designers and engineers then convert these ideas into precise, innovative plans. Next, we carefully process raw materials and shape them into robust components. Skilled hands and advanced technology assemble these parts into a unified structure. Our team then conducts rigorous quality checks to ensure each vehicle delivers strength, safety, and top performance. Once perfected, we deliver the machine—ready to hit the road and drive India’s growth.

How a Trusted Tip Trailer Manufacturer in India Sources Quality Raw Materials

We begin by carefully sourcing high-grade raw materials such as mild steel, aluminum, glass, rubber, and electrical components from certified vendors. Furthermore, we start quality assurance at this stage by subjecting every material to stringent testing. As a result, we select only the best and most reliable inputs. In addition, this early focus on quality builds a strong foundation for excellence throughout the entire production process.

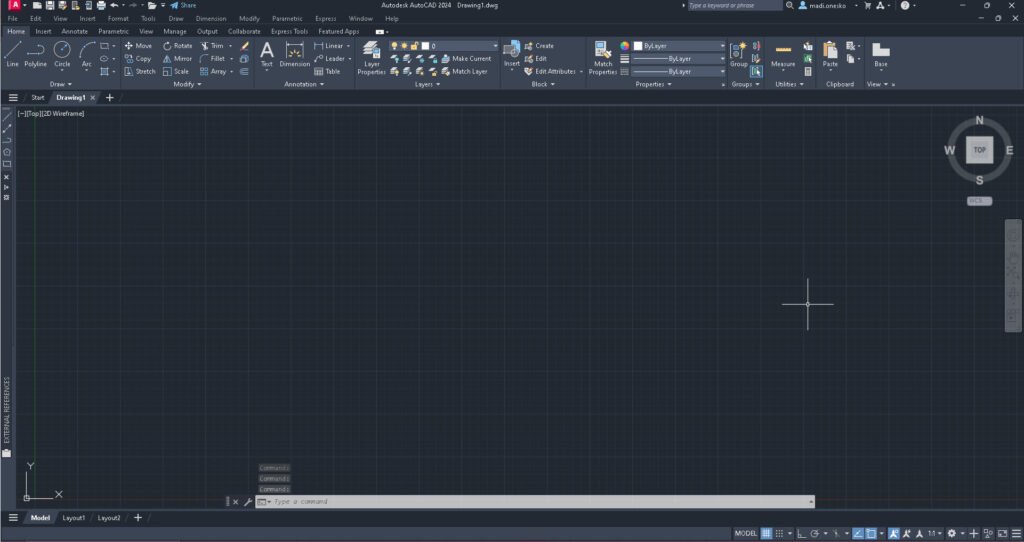

CAD Design and Engineering

Our design engineers use advanced CAD software to create vehicle body blueprints tailored to client needs—whether it’s a municipal garbage tipper, a defense supply vehicle, or a refrigerated truck.

Fabrication and Cutting

Using laser cutting and plasma machines, raw steel sheets are cut and shaped into the required panels and components. Precision in this stage ensures structural integrity and perfect fitment.

Assembly and Welding

Next, our skilled technicians assemble the chassis frame and weld parts together. MIG and TIG welding are commonly used to ensure durability and strength.

Surface Treatment and Painting

We treat the entire structure with processes like shot blasting and primer coating before painting it in our state-of-the-art booth. These steps prevent rust and ensure a long-lasting finish.

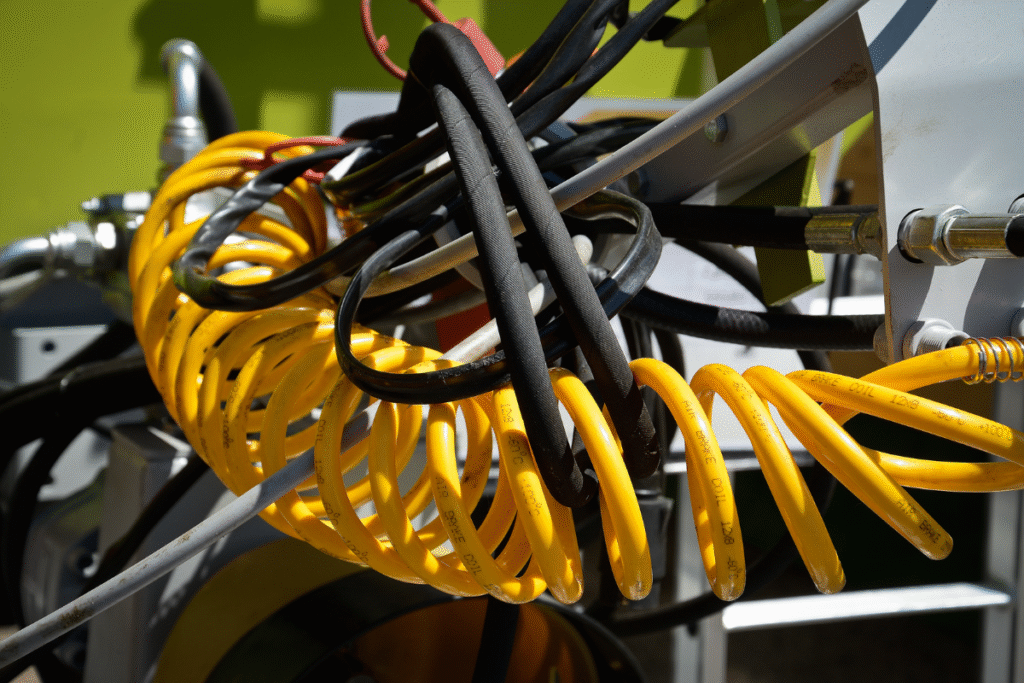

Electrical and Hydraulic Integration

We install electrical systems, hydraulic lifts, and other controls depending on the vehicle type. Every unit is tested thoroughly for safety and performance.

Final Inspection and Quality Check

Our QA team conducts a multi-point inspection that covers build quality, safety parameters, finish, and overall functionality. Vehicles are road-tested before delivery.

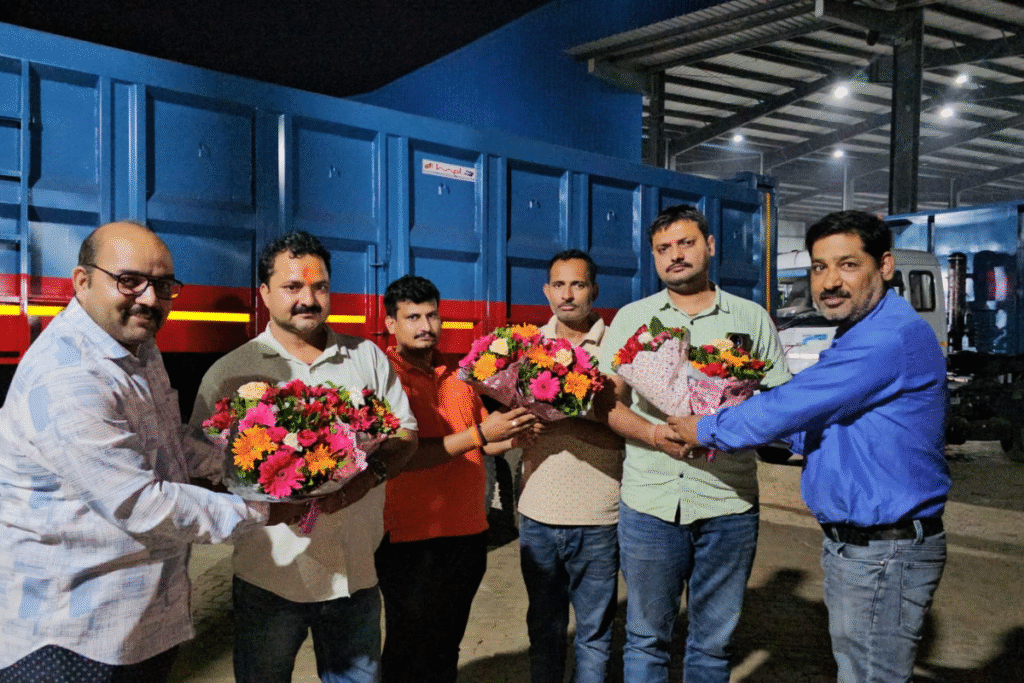

Dispatch and Delivery

Once we approve the vehicles, we clean, sticker, and prep them for dispatch. Our logistics team then delivers them promptly to clients across the country.

Conclusion

At Himatsingka Automobiles, the journey from raw material to road-ready vehicle showcases engineering excellence, skilled manpower, and an unwavering pursuit of quality. We design, craft, and deliver every unit to demonstrate our commitment and strengthen the backbone of India’s transportation and infrastructure.